Product Description

For constructing 3mm x 24 core paraffin tissue microarray block.

Price: $125

Product Description

For constructing 4mm x 15 core paraffin tissue microarray block.

Price: $125

Product Description

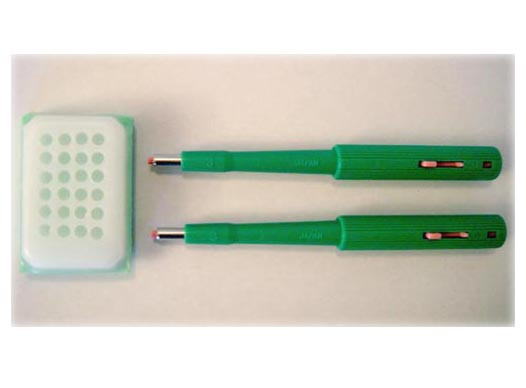

Our Biopsy Punch Needle with Plunger are used for building tissue microarray blocks. Five sizes are available: 1mm, 1.5mm, 2mm, 3mm, 4mm in pack of 4 pcs for each size. It can be used with our EZ-TMA Tissue Array Molds.

Price: $58

Product Description

The EZ-TMA Tissue Array Mold allows users to make paraffin recipient blocks quickly and easily at low cost. If stored and handed with care, hundreds of paraffin recipient blocks can be made with these molds. We have five core sizes available: 1mm x 170, 1.5mm x 72, 2mm x70, 3mm x 40, 4mm x 15.

Price: $699

Product Description

Quick-Ray Mold is made from silicon material and it allows users to build paraffin recipient blocks by themselves at a lower cost. We have five core sizes available: 1mm x 170, 1.5mm x 150, 2mm x70, 3mm x 40, 5mm x 15

Price: $798

Product Description

Arraymold Kit is easy, fast, accurate and inexpensive way to build paraffin and frozen tissue array blocks. We have six sizes available: 1.5mm x 72, 1.5mm x 150, 2mm x 36, 2mm x 60, 3mm x 35, 4mm x 15

Price: $899

Product Description

Our Quick-Ray patented premade recipient block is made of special material that melts when heated at 60˚C for 30 minutes. We have five sizes available: 1mm x 120 wells, 1.5mm x 90 wells, 2mm x 60 wells, 3mm x 30 wells, 5mm x 20 wells.

Price: $50

Product Description

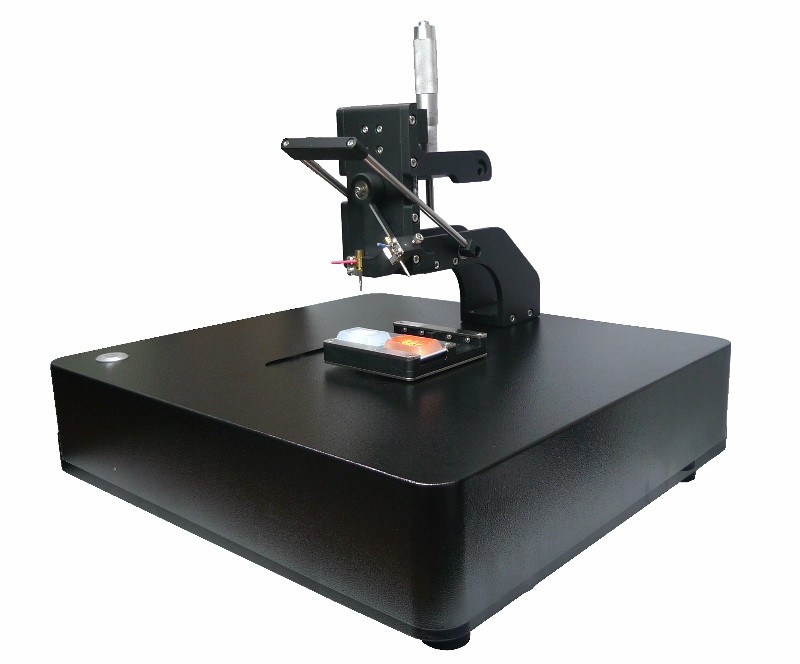

The Quick-Ray® Manual Tissue Arrayer Full Set is used for building five different sized tissue microarrays (1mm x 120 wells, 1.5mm x 90 wells, 2mm x 60 wells, 3mm x 30 wells, 5mm x 20 wells).

Price: $3,800

Product Description

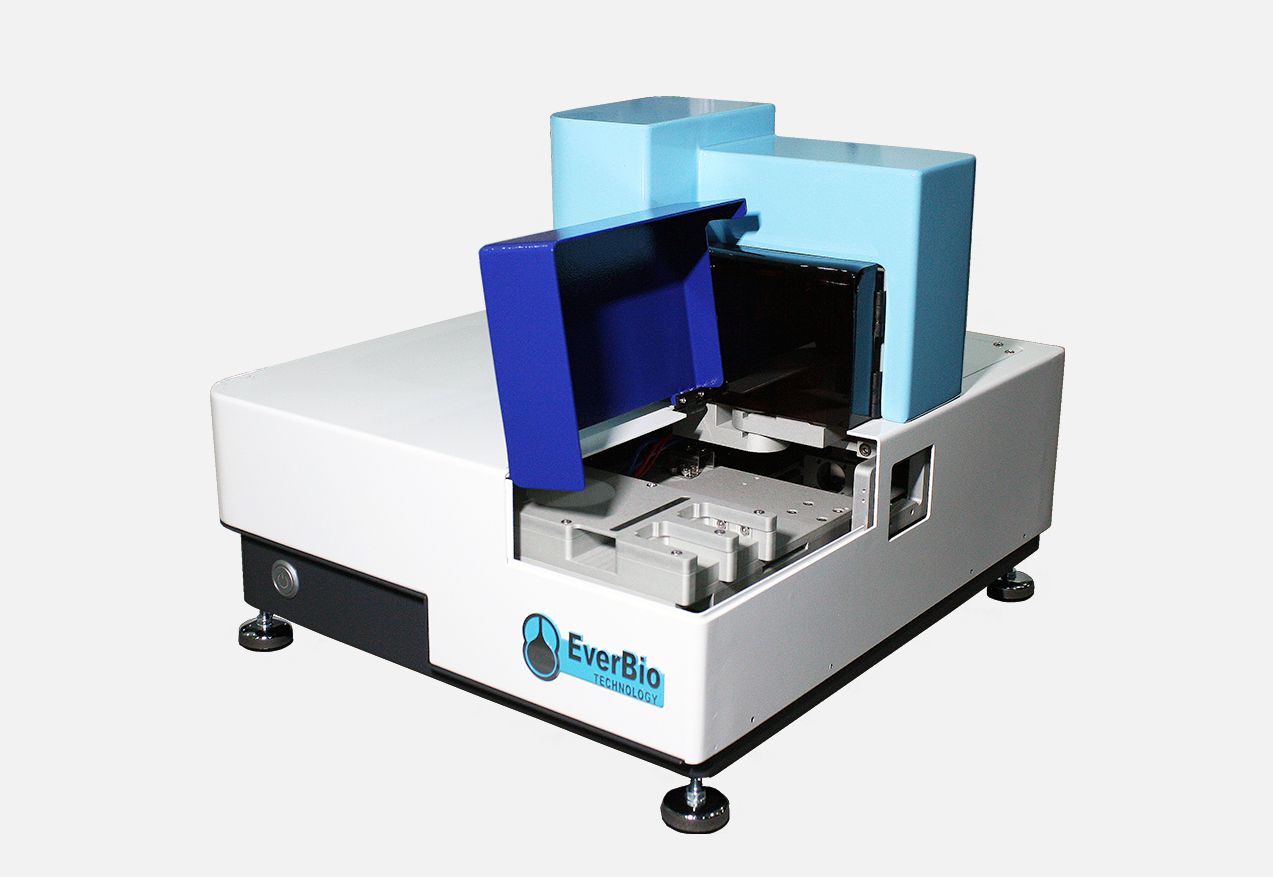

The Quick Ray Master UATM-272B is a newly developed tissue microarrayer running by simply connecting to user's computer through USB port. The changeable tips for the desired core size of the recipient blocks has 4 different sizes which are 1mm (120 holes), 1.5mm (90 holes), 2mm (60 holes), and 3mm (30 holes). UATM-272B is very easy for users to be familiar with the instrument.

Price: $98,000

Product Description

It is a compact, hand carry manual tissue microarray (TMA) arrayer. Durable and handy design with easy operation to make recipient block using “array mold” incorporate with changeable puncher needle sets for different core size.

Price: $1,850

Product Description

AuotTiss One is a compact, hand carry semi-automated tissue microarray (TMA) arrayer. A most cost-effiective upgrade kit for manual TMA puncher.

Price: $25,800

Product Description

Want a fully automated TMA? With budget concern? This most affordable unit gives you the opportunity to upgrade your manual or semi-auto TMA to have the highest donor capacity on the market by connecting it to AutoTiss Loader.

Price: $48,000

Product Description

One of the most innovative invention. Compact and FULLY automated, tissue microarray (TMA) arrayer, which significantly helps the researchers to decrease the time and labor in creating blocks. It can hold up to 10 blocks at a time and five 0.6, 1.0, 1.5, 2.0, 2.5mm punchs sizes are available.

Price: $108,500